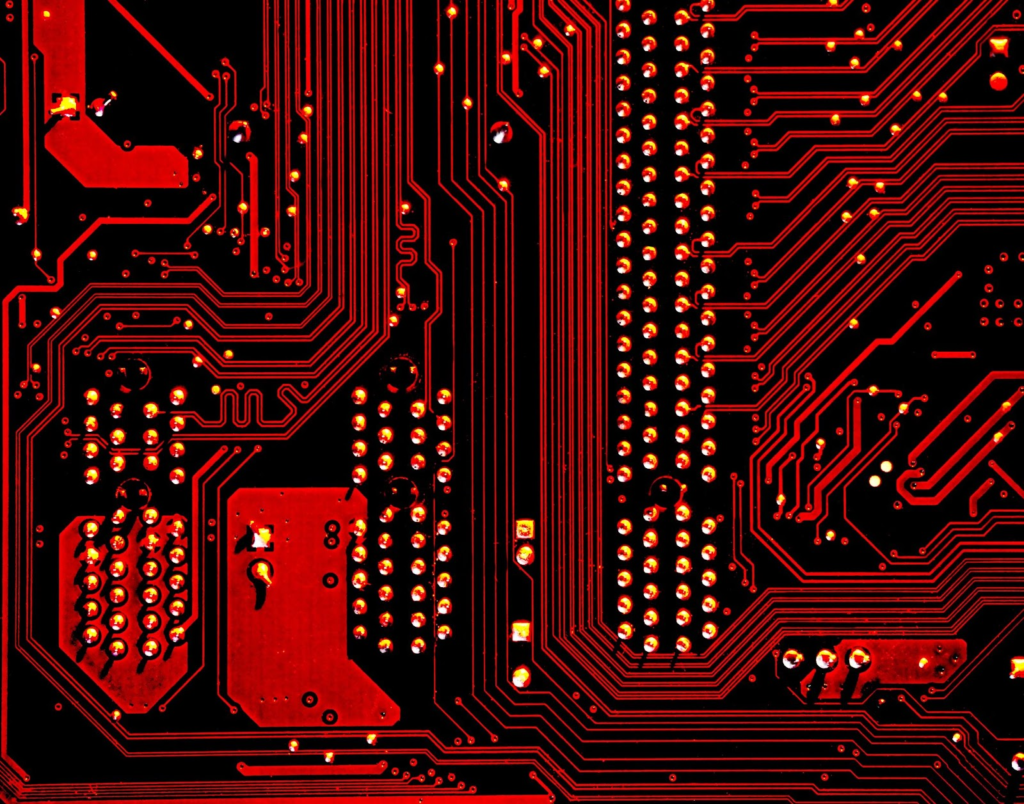

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry with their ability to bend and conform to various shapes and sizes, enabling new design possibilities and product innovations. As consumer demand for smaller, lighter, and more durable electronic devices increases, the need for flexible PCBs is also on the rise.

Table of Contents

What are Flexible PCBs?

Flexible Printed Circuit Boards (PCBs) or simply Flex PCBs are electronic PCBs that can be bent, twisted, and folded without damaging their functionality. These PCBs are made using flexible plastic or polymer materials instead of the rigid materials used in traditional PCBs.

Benefits of Flexible PCBs

Flexible PCBs have numerous benefits over traditional rigid boards. These benefits include:

- Excellent Flexibility and Durability

- Lightweight and Compact

- High Density of Components

- Cost-Effective

- Improved Signal Integrity

- Increased Heat Dissipation

- EMI Shielding

- Reducing Assembly Time

Current Trends in Flexible PCB Technology

Miniaturization of Flexible PCBs

One of the current trends in flexible PCB technology is miniaturization. The demand for smaller devices with the same or even more advanced functionalities is on the rise. The trend has led to the development of flexible PCBs that can accommodate more components in smaller areas.

Improvements in Flex Circuit Materials

The advancement of flexible circuit materials has led to the development of new materials with improved properties. These materials have better thermal and mechanical stability, higher flexibility, and improved electrical conductivity. The improvement in these materials has enabled high-performance flex PCBs with varied applications.

Advancements in Flexible PCB Manufacturing

Flexible PCB manufacturing processes continue to improve. New manufacturing techniques and equipment have been developed to produce flex PCBs with high precision and quality. Advancements in manufacturing have also led to reduced production time, lower costs, and increased production capacity.

Future Direction of Flexible PCBs

Flexible PCBs have revolutionized the tech industry by enabling the creation of wearable devices, IoT devices, and smart home systems. In the coming years, they are set to become even more prevalent in these areas.

Increased Demand for Wearable Technology

As the demand for wearable technology continues to rise, so does the need for flex PCBs that can withstand the constant bending and twisting that comes with wearables. The future of flex PCBs is headed towards even thinner, lighter, and more durable designs that will enable wearable devices to be more comfortable and user-friendly.

Advanced Internet of Things (IoT)

The Internet of Things (IoT) is a network of interconnected devices that communicate with each other to automate processes and improve efficiency. With the development of advanced IoT technologies, the need for flex PCBs that can be easily integrated into a variety of devices is becoming increasingly important. Flex PCBs will be critical for IoT devices that need to be small and light enough to be placed almost anywhere.

Flexible PCBs for Smart Homes and Cities

Flexible PCBs will also have a significant impact on the growth of smart homes and cities. These devices will help to create more efficient energy systems, as well as provide better connectivity and functionality in various appliances. By being able to bend and shape to fit specific areas, flex PCBs will allow for custom designs that can be integrated into existing infrastructure with ease.

Innovations in Flexible PCB Design and Manufacturing

The manufacturing process for flexible PCBs has evolved significantly in recent years. With more advanced technologies, innovation in flexible PCB design and manufacturing is heading toward even more exciting possibilities.

3D Printing of Flexible PCBs

One of the most notable innovations in flexible PCB design is the ability to 3D print them. This process allows for rapid prototyping and customization of flexible PCBs, which is particularly useful in the development of wearable technology and IoT devices. 3D-printed flex PCBs can also be more efficient, cost-effective, and environmentally friendly than traditional manufacturing methods.

Flexible Hybrid Electronics (FHE)

Flexible Hybrid Electronics (FHE) is a promising new area of technology that combines the flexibility of PCBs with the power of silicon chips. The result is a more durable and versatile form of electronics that can be used in a broad range of applications, from wearable technology to automotive products.

Flexible PCB Prototyping with Virtual Reality (VR)

Virtual Reality (VR) is another technology that is being used to advance the design and manufacturing of flexible PCBs. VR enables designers to visualize and test the functionality of flex PCBs in a virtual environment before they are produced. This technology is set to revolutionize the flexible PCB prototyping process, speeding up the development cycle and reducing costs.